There’s a notion that Electronics Manufacturing Services (EMS) companies are only there to build sub-assemblies to order, test, distribute and sometimes provide return/repair services.

This is not true!

The prevailing myth is that when an OEM (Original Equipment Manufacturer) wants to outsource actual product design, they need to consult an ODM – an Original Design Manufacturing provider – who is likely to offer them a reboot of something they’re already making for another company.

Many experienced EMS companies (we prefer the term ‘manufacturing partner’) can provide equally skilled services at the front-end of the value chain, both designing the product as well as assembling, testing and volume production. In fact there’s a number of ways a manufacturing partner can make valuable contributions to product design.

Retain full control of your Intellectual Property (IP)

ODMs are companies that design and manufacture products for other companies to rebrand and sell as their own. In the typical ODM model, both the control of product design and the associated intellectual property shifts to the suppliers, although it does depend on the OEM’s size.

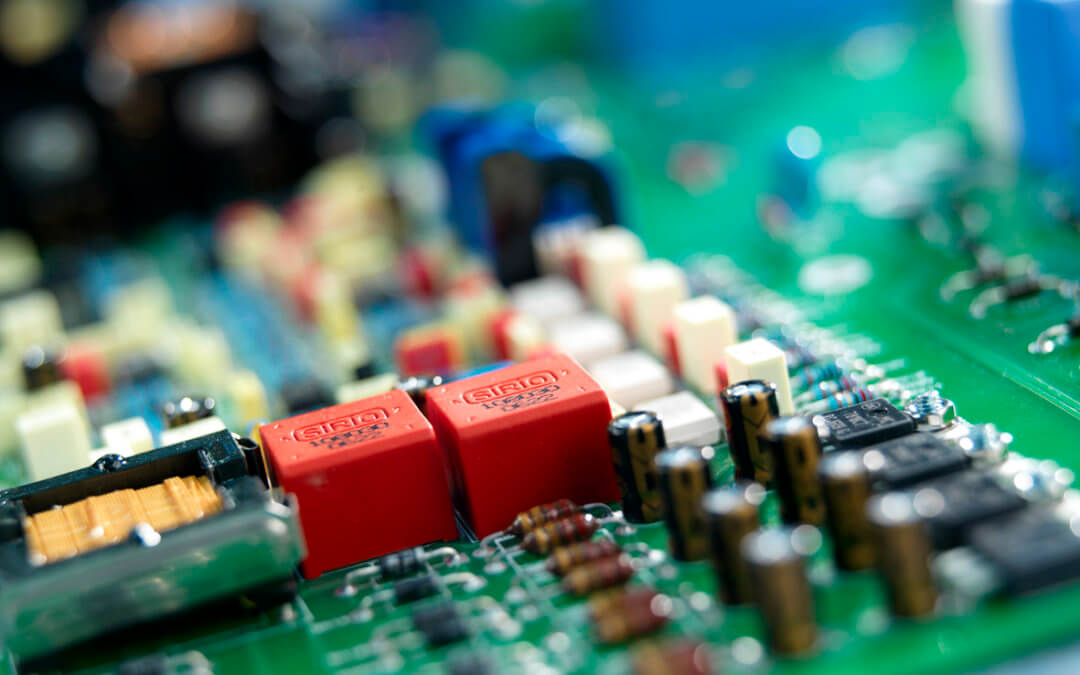

While ODMs have been scaling up in recent years, the trade-off to manufacturers buying ODM services is a significant loss of IP. Variations of PCB design, control boards and interface design have proven to be notoriously difficult and expensive to protect. For this reason, the business presumption is that an ODM will eventually become the OEM’s competitor, whereas an EMS partner works on behalf of an OEM as a service provider and not a competitor.

In a market dominated by OEMs that are rebadging standardised products which have been manufactured according to the same design, it becomes more difficult to differentiate your product from a competitor’s.

Benefit from broader EMS capabilities

A mid-size OEM might introduce 10 or 20 prototype designs in a year, or even fewer, whereas an EMS partner, set up to deliver volume and efficiency, will produce several hundred in the same time period. When EMS providers engage with customers early in the design process, they can apply their combined years of industry expertise and innovation to ensure the end result is as effective and efficient as possible. For example, we have accomplished engineering staff aligned to all aspects of design from pure PCB design and assembly to mechatronics, software engineering, COTS (commercial off-the-shelf) module integration, interface design, electrical design, enclosures, prototyping, testing and certifications or any task that brings life to a product.

Align component selection to Design for Manufacturing (DfM) principles

A customer may present us with schematics for a product design that aren’t feasible or could be improved. A problem we increasingly encounter is when hard-to-source MLCCs (Multi-Layer Ceramic Capacitors) are specified instead of more readily available polymer alternatives. It could be they’ve designed-in an EOL (End of Life) component or they’re proposing a needlessly complex PCB layout.

Early engagement allows for product optimisation using DfM principles. This is the practice of designing products with the manufacturing process in mind, choosing the best processes, materials and components. For example, we look at ways to minimise the use of new ‘active parts’ in favour of standardised, widely available components, as the design of a new part is usually only the best option from a purely inventive design point of view. DfM addresses this by asking designers to consider not what could be created, but what should be created. Minimising active parts through standardisation simplifies product design and leads to operational efficiencies through lower inventories.

DfM is not about discouraging creativity and new solutions; sometimes it is necessary to develop a new part. However, this approach ensures manufacturing costs stay low without cutting corners and the best results are achieved without compromising on quality or performance.

Help with front-loading the manufacturing process

Once a design is released to production, and especially after it has been validated for regulatory compliance, the costs of changing the design may be prohibitive. In fact, decisions made during the design phase determine 70% of the product’s final cost. There is often a singular, and closing, window of DfM opportunity that must be grasped to avoid later complications. Working closely with contract manufacturers while designs are still fluid ensures that both manufacturing and supply chain considerations are factored into your manufacturing plans.

By front-loading the process, an early review of all the commercial aspects of the design can be conducted, including but not limited to:

- Design resilience and compliance aspects

- Product and process design that balances product quality against design effort

- The effort involved to design new active parts and costs of inventories

- Use of alternatives for volume-friendly production

- Use of standard parts, COTS modules, etc

- Global sourcing and associated obsolescence issues

- Selection of “machine friendly” packaging formats

Let’s take a look at some of these in more detail.

Designing to save cost on material spend

Component cost is a significant factor of DfM. Material spend makes a big difference to OEM profit, especially during uncertain times of fluctuating supply and currencies. By consolidating OEM material spending, an EMS provider will gain a 10-100 fold increase in spending power, providing direct access to global manufacturing channels and cutting out the proverbial ‘middle man’. This is how we can overcome minimum order quantity (MOQ) restrictions and access the very best price breaks. Also, a larger EMS material spending power means that components can be sourced in machine-friendly formats which increase automation and traceability, further enhancing product integrity and overall performance.

Factoring-in supply-chain considerations

Component availability and obsolescence issues are increasingly a problem for product design. We are well positioned to help a customer navigate through these issues. Even the most perfectly designed electronics assembly, presenting zero fabrication, regulatory or inspection issues can create critical delays and costly substitutions if components are not sustainably available.

These supply chain breaks may be due to:

- Changes in distribution

- Components being placed on EOL

- Stocks being allocated as they run low

- Or mergers and acquisitions creating ever-widening ripples

Product design engineers are often focused on component selection to achieve the desired functional performance and sometimes struggle to see beyond the immediate prototype or small-batch production stages.

We provide valuable input to help create selections that are sustainable and cost-effective, addressing future requirements when the product ramps into eventual production volumes or off-shore manufacturing locations.